#simulation software for additive manufacturing

Explore tagged Tumblr posts

Text

AM PravaH: 3D Printing Software By Paanduv Applications

About the case study

This document will help you run your first AM PravaH LPBF simulation for macroscale and microstructure modeling. The case study is done for a standard alloy of titanium i.e. Ti6Al4V widely used for aerospace and biomedical applications. The simulation is carried out for a multilayer, multi-track scan pattern. The process parameters for the laser are e.g. 300 W power and e.g. 1 m/s scan speed. D4 sigma or spot dia is 0.1 mm.

Exclusive features of AM PravaH include consideration of 4 phases, with no explicit formulation for recoil pressure because evaporation and recoil pressure effects are included in the vapor phase. AM PravaH takes the thermophysical properties of the 4 phases as inputs along with the process parameters such as laser power, laser scan speed, shielding gas flow angle and velocity, layer thickness, spot diameter, preheating temperature, chamber initial pressure, and substrate initial height, scan pattern, particle size distribution and number of layers. Macroscale modeling will generate the following outputs melt pool dimensions, porosity %, thermal gradients, cooling rates, and thermal cycling plots. The Microstructure module generates outputs such as grain size distribution, angular chord length distribution, misorientation angles, and Euler angles. AM PravaH leverages the amalgamation of computational modeling solvers performing multiphase macroscale modeling, microstructure modeling, and Artificial Intelligence (AI) at a unified platform.

Keywords: Additive Manufacturing, 3D printing, Meltpool dynamics, porosity, thermal gradients, cooling rate, microstructure analysis, grain size, angular chord length, 3D printing software

AM PravaH: 3D printing simulation software

Introduction

AM PravaH is a 3D printing simulation software that facilitates end-to-end solutions for Additive Manufacturing physics-based simulations. Additive Manufacturing is commonly known as 3D printing. This 3D printing software is the “World’s first all-inclusive 3D computational software for Additive Manufacturing”. This 3D printing software will be useful for new alloy development, process parameter optimization, and reducing defects. Not to confuse with other 3D printing software that only performs thermomechanical analysis and deformation, AM PravaH software offers much more.

The software capabilities in brief are as follows:

There are three modules in AM PravaH

(i) Macroscale modeling

(ii) Microstructure analysis

(iii) Integrated Deep Learning (AI) module

Relevance of the 3D printing software; AM PravaH

This 3D printing software is relevant for researchers, academicians, and industry professionals from large and small-sized companies working in the Additive Manufacturing field. Where the primary focus is to understand the in-depth physics, microstructures, and effect of process parameters on the melt pool dynamics and distribution and the root cause of the defects. If we have a much closer look at the fundamental processes of 3D printing; this is a transient, very quick, and very dynamic process, which can't be captured with the naked eye. Therefore, AM PravaH simulations can be extremely useful in understanding this part.

Based on that, one makes important decisions such as

Which alloy is better?

How do we get solidification, melting, and cooling rates information?

what are the best operating process conditions to get a defect-free and dense part

What do the microstructures look like?

What are the grain distribution and mean grain size?

What are the melt pool sizes?

How much will be the porosity %?

#3d printing simulation software#3d printing software#additive manufacturing software#additive manufacturing#3d printing#simulation software for additive manufacturing

1 note

·

View note

Text

Top 8 Applications of 3D Printing in Medical Industry

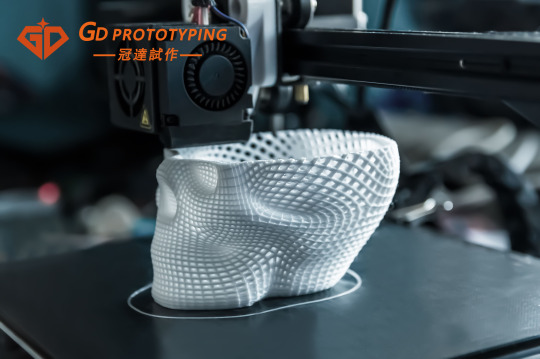

3D printing technology, with its highly customizable, responsive and material-saving features, is triggering profound changes in the medical field. Especially in the application of medical models, 3D printing technology shows unparalleled advantages and potential.

Furthermore, 3D printing technology, as an emerging additive manufacturing technology, has made breakthroughs in its application in the medical field in recent years. The application of 3D printing technology in the medical field is becoming more and more widespread. Through the layer-by-layer stacking of digital models, a variety of medical devices, prosthetics, orthotics and other aids, and even human organs, can be accurately printed.

1.Surgical preview model

With 3D printing technology, doctors can create surgical preview models to help them simulate operations before surgery, improving accuracy and safety.

It is important for medical workers to conduct preoperative planning for risky and difficult procedures. In the previous surgical preview process, medical workers often need to obtain the patient's data through CT, magnetic resonance imaging (MRI) and other imaging equipment, and then the two-dimensional medical image using software to convert into realistic three-dimensional data. Today, medical workers can use devices such as 3D printers to print 3D models directly. In this way, it not only can assist the doctor to carry out accurate surgical planning, improve the success rate of surgery, but also to facilitate the communication and exchange between medical workers and patients on the surgical program plan.

2.Surgical guide

Surgical guides can help the surgeon to accurately position and operate during surgery, reducing surgical errors and improving surgical outcomes.

As an auxiliary surgical tool during surgery, surgical guides can help medical workers to accurately implement surgical programmes. Currently, the types of surgical guides have included joint guides, spinal guides, oral implant guides, etc. With the help of 3D printed surgical guides, firstly, the 3D scanning technology can produce three-dimensional data on the patient's affected area, which allows the doctor to obtain the most realistic information, so as to better plan the surgery. Secondly, while making up for the shortcomings of the traditional surgical guide manufacturing process, the size and shape of the guide can also be adjusted as needed.In this way, different patients can have a guide plate that meets their real needs.

3.Dental applications

3D printing technology is also widely used in the field of dentistry to print personalized trays, moulds, etc., to help patients have better dental treatment.

The application of 3D printing in the dental field mainly focuses on the design and production of metal teeth, invisible braces, etc. The emergence of cutting-edge technology of 3D printing creates more possibilities for those who need orthodontic treatment to achieve personalized and customized braces. At different stages of orthodontic treatment, orthodontists need different sets of braces. With the help of 3D printing to create multiple sets of braces needed for orthodontic treatment, it not only helps the healthy development of teeth, but also reduces the cost of braces production. The significance of these digital technologies is that they are gradually making it less necessary for doctors to make models, dentures, etc. by hand, and returning more of their efforts to the diagnosis of oral diseases and the performance of oral surgery itself.

4.Rehabilitation medical equipment

Through 3D printing technology, a variety of rehabilitation medical devices, such as prosthetics and orthotics, can be created to help patients regain function.

The real value of 3D printing for orthopaedic insoles, bionic hands, hearing aids and other rehabilitation devices is not only to achieve accurate customization, but also to allow accurate and efficient digital manufacturing technology to replace the traditional production methods, reducing the cost of individual customized rehabilitation medical devices and shortening the production cycle. 3D printing process is diversified, and there is a wide range of 3D printing materials. SLA light-curing 3D printing technology has the advantage of being able to provide the most efficient and cost-effective 3D printing technology. SLA light-curing 3D printing technology is widely used in rapid prototyping by the medical device industry due to its advantages of fast processing speed, high precision, good surface quality of photosensitive resin material moulding and moderate cost.

5.Medical Equipment Cases

3D printing technology can also be used to create a variety of medical devices, such as surgical instruments and medical equipment, to improve the personalization and accuracy of medical devices.

Take the example of 3D printing for mass customized production in the hearing aid shell industry. In the traditional way, injection moulds need to be made from a model of the patient's ear canal. The final shape of the hearing aid is obtained by drilling sound holes and manually processing the plastic product. If a mistake is made during the process, the mould needs to be recreated. The process of making a hearing aid using a 3D printer, on the other hand, begins with the design of a silicone mould or impression of the patient's ear canal, a step that is done using a 3D scanner. CAD software is then used to convert the scanned data into a design file that can be read by the 3D printer. The designer can then use the software to modify the 3D image and create the final product shape.

6.Precision replication and personalization

3D printing technology is able to accurately restore a patient's anatomy and produce full-size, high-fidelity medical models based on the patient's CT, MRI and other imaging data. These models not only have extremely high geometric accuracy and surface quality, but also reflect the unique physiological characteristics of the patient, providing doctors with real and reliable references.

7.Teaching and training

3D printed medical models also play an important role in medical education and training. By printing out models of various typical cases, medical students can perform practical operations in a simulated surgical environment to enhance their surgical skills and resilience. At the same time, these models can also be used as teaching tools to help students better understand human anatomy and disease principles.

8.Scientific research and experimentation

In the field of medical research, 3D printed medical models also have important applications. Researchers can use these models to conduct experimental studies such as drug screening and biomechanical testing to explore new treatment methods and technologies. In addition, by printing tissue or organ models with specific physiological functions, they can also provide strong support for research in cutting-edge fields such as organ transplantation and regenerative medicine.

In summary, 3D printing technology has a wide and far-reaching significance in the application of medical models. It not only improves the accuracy and efficiency of medical services, but also promotes the innovative development of medical education, research and clinical practice. With the continuous progress of technology and the expansion of application scope, we have reason to believe that 3D printing will play a more important role in the future medical field.

#3d printing#3d printing services#3d printed#additive manufacturing#3d print#medical device machining#medical 3d printing#3d printed parts#3d printing materials market#3d printing market share

4 notes

·

View notes

Text

Yvette Heiser - How Phone Photography Has Transformed Over the Years

In the past two decades, phone photography has undergone a remarkable transformation, evolving from a novelty feature to a vital tool for both amateur and professional photographers. As smartphones have become ubiquitous, so too has the ability to capture high-quality images at any moment. Yvette Heiser talks about - How Photography Has Evolved Over the Years, highlighting the technological advancements that have revolutionized mobile photography, from improved sensors to AI-enhanced editing tools, making it easier than ever to take stunning photos with just a phone.

The Early Days of Mobile Photography

A Simple Beginning

The journey of phone photography began in the early 2000s with the introduction of basic camera phones. These devices featured low-resolution cameras, often producing images that lacked clarity and detail. The primary purpose of these cameras was to share quick snapshots rather than create high-quality photographs.

In 2002, the first commercially available camera phone, the Sharp J-SH04, was launched in Japan. It had a mere 0.11-megapixel sensor, which limited its capabilities. Early users primarily captured simple images for texting or sharing with friends. The quality was far from impressive, but it sparked a new way of documenting everyday life. Yvette Heiser Texas: A Complete Guide to Mastering Phone Photography explores this evolution, offering insights into how phone cameras have advanced over the years and how users can harness their full potential for stunning photography.

The Rise of Social Media

As social media platforms like Facebook and Instagram gained popularity in the late 2000s, so did the demand for better mobile photography. Users wanted to share their lives through images, prompting manufacturers to improve their camera technology. This shift marked a turning point in how people viewed phone photography.

Technological Advancements in Camera Phones

Improved Camera Quality

By the time the iPhone was introduced in 2007, mobile photography began to take a significant leap forward. The iPhone's 2-megapixel camera offered improved image quality compared to its predecessors. Over the years, subsequent iPhone models and other smartphones began to feature higher-resolution cameras with better sensors and optics.

Megapixels Matter: Modern smartphones now come equipped with cameras boasting 12-megapixels or more, allowing users to capture stunning images with remarkable detail.

Multiple Lenses: Many devices now include multiple lenses—wide-angle, telephoto, and macro—enabling users to experiment with different perspectives and styles.

Advanced Software and Features

In addition to hardware improvements, software enhancements have played a crucial role in transforming phone photography. Image processing algorithms have evolved significantly, enabling smartphones to produce high-quality images even in challenging lighting conditions.

Some notable advancements include:

Night Mode: This feature allows users to capture clear and vibrant images in low-light environments without using a flash.

Portrait Mode: By simulating depth of field, portrait mode helps create professional-looking photos by blurring the background while keeping the subject sharp.

AI Integration: Many smartphones now utilize artificial intelligence to enhance photos automatically, optimizing settings based on scene recognition.

The Influence of Social Media on Mobile Photography

The Pursuit of Perfection

Social media platforms have greatly influenced how people approach photography with their phones. The desire for likes and shares has led to a focus on aesthetics and creativity. Users are now more aware of composition, lighting, and editing techniques, resulting in a generation of visually-savvy photographers.

The Rise of Influencers

With the advent of social media influencers, mobile photography has become an essential skill for many aspiring content creators. Brands are increasingly collaborating with influencers who possess a strong visual storytelling ability through their smartphone photography. This trend has further pushed smartphone manufacturers to innovate and provide users with tools that cater to this growing market.

Mobile Photography as a Form of Art

Breaking Down Barriers

Today, phone photography is no longer just about capturing memories; it has become a legitimate form of art. Many photographers have transitioned from traditional cameras to smartphones, showcasing their work in galleries and exhibitions. This shift has democratized photography, allowing anyone with a smartphone to express their creativity.

Community and Collaboration

The rise of mobile photography communities has also contributed to its evolution. Platforms like Instagram have fostered connections among photographers, leading to collaborations and shared learning experiences. Users can now participate in challenges and workshops focused on improving their skills and showcasing their work.

Future Trends in Phone Photography

Continuous Innovation

As technology continues to advance, we can expect even more exciting developments in phone photography. Here are some trends that may shape the future:

Enhanced Image Stabilization: Future smartphone cameras will likely include advanced stabilization technologies that allow for smoother video recording and sharper still images.

Augmented Reality (AR): With AR applications becoming more popular, we might see features that enable users to overlay digital elements on their photos or create immersive experiences.

Higher Dynamic Range (HDR): Improved HDR capabilities will likely enhance the quality of photos taken in high-contrast environments, ensuring details are preserved in both highlights and shadows.

Sustainability and Ethical Considerations

As mobile photography grows, so does awareness of sustainability and ethical considerations in photography practices. Photographers are increasingly encouraged to consider their impact on the environment and seek ways to promote responsible practices.

Conclusion

The transformation of phone photography over the years has been nothing short of extraordinary. From its humble beginnings with basic camera phones to the sophisticated devices we use today, mobile photography has revolutionized how we capture and share moments. As technology continues to evolve, it will undoubtedly open new doors for creativity and expression. Whether you’re an aspiring photographer or simply enjoy documenting your daily life, embracing the art of phone photography offers endless possibilities for exploration and connection.

#wedding#camera#photographer#pictures#childphotography#moments#photography#yvette heiser#photographytips#events

6 notes

·

View notes

Text

2D to 3D Drawing Conversion Services: Transforming Designs with Precision

2D to 3D Drawing Conversion Services: Transforming Designs with Precision

Introduction

In the modern design and engineering world, the transition from 2D to 3D drawings has become crucial for enhanced visualization, accuracy, and efficiency. At ADSBIM, we specialize in 2D to 3D drawing conversion, offering precision-driven solutions to transform flat drawings into comprehensive 3D models. Our expertise ensures seamless conversion, catering to industries like architecture, engineering, and manufacturing. We are recognized as the BEST 2D to 3D Drawing Conversion Services provider in Gurgaon, India, UK, Dubai, and USA.

The Process of Converting 2D Designs into 3D Models

The 2D to 3D drawing conversion process involves several meticulous steps to ensure accuracy and fidelity to the original design. Here’s how we do it:

Understanding Requirements: We analyze the 2D drawing, ensuring clarity in dimensions, annotations, and details.

Software Selection: Based on project needs, we choose the appropriate 2D to 3D drawing conversion software such as AutoCAD, SolidWorks, Revit, or CATIA.

Modeling the Geometry: Using advanced tools, we create a 3D representation of the 2D drawing while maintaining proportional accuracy.

Material and Texture Application: If required, materials, textures, and colors are applied to make the model more realistic.

Validation and Quality Check: The final 3D model is compared with the original 2D drawing to ensure precision and adherence to client requirements.

Final Delivery: The completed 2D drawing to 3D model is delivered in the required format, ready for use in design simulations, manufacturing, or visualization.

Challenges in 2D to 3D Drawing Conversion

While converting 2D drawings to 3D models, several challenges can arise:

Loss of Information: Some 2D drawings lack depth-related data, requiring intelligent interpretation.

Complex Geometries: Intricate designs may need additional modifications to ensure a smooth 3D transformation.

Scale and Accuracy: Ensuring precise measurements during conversion is crucial to avoid design flaws.

Software Compatibility: Different clients use varied software, requiring expertise in multiple platforms.

How ADSBIM Provides the Best Solutions

At ADSBIM, we tackle these challenges with expertise and cutting-edge technology:

Experienced Team: Our skilled professionals have extensive experience in 2D to 3D drawing conversion across multiple industries.

Advanced Software Tools: We use industry-leading 2D to 3D drawing conversion software, including:

AutoCAD

SolidWorks

Revit

CATIA

SketchUp

Custom Solutions: We tailor our approach to match specific project needs, ensuring maximum accuracy.

Quality Assurance: Rigorous quality checks ensure error-free 2D drawing to 3D model conversion.

Fast Turnaround: Our efficient process ensures timely delivery without compromising quality.

Why Choose ADSBIM for 2D to 3D Drawing Conversion?

BEST 2D to 3D Drawing Conversion Services COMPANY IN GURGAON and globally recognized in India, UK, Dubai, and USA.

Precision and Accuracy: Our models maintain the highest standards of accuracy.

Affordable Solutions: We provide competitive pricing while maintaining high quality.

Comprehensive Support: From consultation to post-conversion support, we ensure seamless collaboration.

Multi-Industry Expertise: We cater to architecture, engineering, manufacturing, and more.

FAQs for 2D to 3D Drawing Conversion Services

What is the benefit of converting 2D drawings to 3D models?Converting 2D to 3D drawing enhances visualization, accuracy, and efficiency, making designs easier to understand and modify.

Which industries require 2D to 3D drawing conversion services?Industries like architecture, engineering, manufacturing, automotive, and product design benefit from BEST 2D to 3D Drawing Conversion Services.

Which software is used for 2D to 3D drawing conversion?We use AutoCAD, SolidWorks, Revit, CATIA, and SketchUp for 2D to 3D drawing conversion software solutions.

How much time does it take to transform a 2D drawing into a 3D model?The time required depends on the complexity of the drawing and project specifications, but we ensure fast turnaround times.

Do you provide 2D to 3D drawing conversion services globally?Yes, ADSBIM offers BEST 2D to 3D Drawing Conversion Services in India, UK, Dubai, USA, and beyond.

Conclusion

The transition from 2D drawing to 3D is essential for better visualization, accuracy, and manufacturing efficiency. With ADSBIM’s 2D to 3D drawing conversion services, businesses can seamlessly transform their designs into high-quality 3D models. Whether for prototyping, construction, or product development, we provide precise, reliable, and cost-effective solutions tailored to your needs.

Looking for expert 2D to 3D drawing conversion services? Contact ADSBIM today and let us bring your designs to life!

#adsbim#2Dto3DConversion#2Dto3DServices#DrawingConversion#CADConversion#3DModeling#AutoCAD#SolidWorks#Revit#CATIA#SketchUp#ArchitectureDesign#EngineeringDesign#ManufacturingDesign#ProductDesign#2Dto3DModeling#DesignVisualization#ADSBIM#Gurgaon#India#UK#Dubai#USA#CADExperts#TechnicalDesign#3DRendering#EngineeringSolutions

3 notes

·

View notes

Text

Menkyo no Tetsujin was a driving game released in very limited capacity by Sega in 2005. The hardware and software were based on the SLDS-3G driving simulator Sega manufactured for Japanese driving schools, but with the addition of a Challenge Mode and IC cards to save progress.

23 notes

·

View notes

Text

Know About The Significance of CNC Machining Companies

An age of industrial accuracy like none before has arrived thanks to CNC machining. Traditional machining techniques sometimes require manual involvement, which might lead to irregularities and human mistakes. On the other hand, CNC machining uses computer-controlled instructions to accurately control tools and equipment. In addition to guaranteeing consistency in completed goods, this degree of precision also lessens the demand for frequent quality control inspections.

Unlimited Possibilities

CNC machining businesses provide a wide range of capabilities, from straightforward two-dimensional cuts to intricate multi-axis operations. This adaptability enables manufacturers to create complex geometries and forms that were previously thought to be impossible. CNC machining provides options for both sides of the spectrum, whether it's manufacturing a huge number of standardized components or developing prototypes with a specific design in mind.

Reduced Turnaround Times: The days of laborious hand setups and modifications in manufacturing are long gone. CNC machining services automate most of the manual work, streamlining the production process. Manufacturing lead times are greatly shortened as a result of this setup time reduction and the ability to conduct automated, uninterrupted operations. Now, businesses can react quickly to market needs and design modifications without compromising on quality or efficiency.

Cost-Effectiveness

The long-term advantages of CNC machining technology are without a doubt worth the initial financial outlay, which might be significant. Once set up, the devices can run independently with little assistance from humans. Reduced labor costs, fewer mistake rates, and improved resource utilization result from this. Additionally, the accuracy of CNC machining reduces material waste, which helps to reduce total costs.

CNC machining businesses are at the vanguard of innovation, according to Innovation Unleashed. They constantly push the limits of what is possible by integrating cutting-edge software, simulation tools, and additive manufacturing processes. Complex design creation and quick prototype iteration have enabled ground-breaking developments in industries including aerospace, healthcare, automotive, and electronics.

Personalization and Customization

Personalization and customization are crucial in today's consumer-driven environment. CNC machining companies that provide CNC machining meet this need by giving customers the freedom to design one-of-a-kind items or small batches that are suited to certain specifications. This degree of personalization boosts consumer satisfaction while also creating new market opportunities and specialized markets.

#CNC Machining#CNC Machining services#CNC Machining companies#Custom CNC Machining Service#Online CNC Machining Services#3 axis CNC machines

3 notes

·

View notes

Text

Belgian Air Force refuses to accept the first finished F-35 aircraft

Diego Alves By Diego Alves 08/07/2023 - 11:00am Military

The assembly of the first two F-35A for the Belgian Air Force began at the Lockheed Martin factory in Fort Worth. Under the terms of the contract for the supply of 34 units of the F-35A, the first two aircraft must be ready and transferred by the end of the year.

However, the Belgian Air Force refuses to accept the first aircraft finished with the AY-01 tail number, which has already left the final assembly line. According to the Belgian military department, the first two AY-01 and AY-02 aircraft that is being completed do not meet the technical requirements of the modification of Block 4.

F-35 production line.

It should be noted that in the purchase contract it was specified that the aircraft would be delivered in the most modern version available. Currently, the latest modification is the Block 4 version, with which the F-35A should receive a lot of news.

This modification includes a new TR-3 integrated central processor with greater processing power, a panoramic cockpit screen, an improved memory unit, a new radar, an electronic warfare system, the ability to use modern weapons and other upgrades.

According to an announcement by Lockheed Martin, these updates will make the stealth aircraft more resistant to modern ground and air threats, both in offensive and defensive missions. Work is underway to further integrate and certify the TR-3 processor, which will take longer than previously expected.

The installed processor of the previous generation TR-2 does not have the necessary power reserve for the new modification of Block 4. It is now expected that all work on the new version will be completed in the second quarter of 2024.

The Belgian Air Force will not accept F-35A fighters until its upgrade to the Block 4 version with the TR3 processor is completed and until the fighter is fully tested and certified, the Belgian Ministry of Defense said.

Are TR-2 and TR-3 processors used ?? in the F-35 fighter, but they serve different purposes. The TR-2 is responsible for handling the aircraft sensor data, while the TR-3 is responsible for running the jet's mission software. This division of labor allows for more efficient processing and better overall performance of the F-35.

The TR-2 processor is manufactured by BAE Systems and is based on the PowerPC architecture. It is responsible for the data processing of the various sensors of the F-35, including radar, electro-optical sight system and electronic warfare system. The TR-2 is designed to handle large amounts of data quickly and efficiently, allowing the F-35 to quickly identify and track targets in the air and ground.

The TR-3 processor, on the other hand, is manufactured by Lockheed Martin and is based on the ARM architecture. It is responsible for running the F-35 mission software, which includes flight controls, weapons systems and communication systems. The TR-3 is designed to be highly reliable and safe, ensuring that the F-35 can complete its missions safely and effectively.

F-35 simulator. Illustrative image.

The TR-3 processor is better than the TR-2 in the F-35 because it has a higher clock speed, which allows it to process information faster. This means that the F-35 can perform more complex tasks and respond more quickly to changes during combat.

In addition to its higher clock speed, the TR-3 processor also has more cache memory than the TR-2. This allows you to store more data in the processor, which reduces the time required to access this data. As a result, the F-35 can process information faster and more efficiently.

The TR-3 processor also has more advanced power management features than the TR-2. This means that it can operate more efficiently, using less energy and generating less heat. This is important for a high-performance aircraft like the F-35, which needs to be able to operate for long periods without overheating or running out of power.

Tags: Military AviationBelgian Air Component wings - Belgian Air ForceLockheed Martin F-35 Lightning II

Sharing

tweet

Diego Alves

Diego Alves

Related news

MILITARY

Su-57 now has an advanced communication package

07/08/2023 - 14:00

MILITARY

U.S. Air Force Reserve makes history with expeditionary air wing in Peru

07/08/2023 - 08:00

OPINION

OPINION: Is Israel excessively dependent on American fighters?

06/08/2023 - 21:20

MILITARY

Paraguayan Air Force prepares to receive its first two modernized T-35 Pillán

05/08/2023 - 13:14

MILITARY

New USAF Operations and Mission Planning Center in Darwin, Australia

04/08/2023 - 15:01

The U.S. Air Force Lockheed U-2, nicknamed Dragon Lady, conducts an aerial demonstration during the 2022 Marine Corps Air Station Miramar Air Show at MCAS Miramar, San Diego, California, Sept. 23, 2022. The U-2, a high-altitude reconnaissance aircraft with U.S. Air Force 9th Reconnaissance Wing, Beale Air Force Base, California, provides day and night, high-altitude, all-weather intelligence-gathering and reaches altitudes above 70,000 feet. The theme for the 2022 MCAS Miramar Air Show, “Marines Fight, Evolve and Win,” reflects the Marine Corps' ongoing modernization efforts to prepare for future conflicts. (U.S. Marine Corps photo by Jose S. GuerreroDeLeon)

MILITARY

USAF will retire U-2 Dragon Lady fleet in 2026

03/08/2023 - 18:00

homeMain PageEditorialsINFORMATIONeventsCooperateSpecialitiesadvertiseabout

Cavok Brazil - Digital Tchê Web Creation

Commercial

Executive

Helicopters

HISTORY

Military

Brazilian Air Force

Space

Specialities

Cavok Brazil - Digital Tchê Web Creation

2 notes

·

View notes

Text

Bim Training Institute in Pune: Elevating Your Career in Building Design

A top Bim Training Institute in Pune offers comprehensive courses that cover all aspects of BIM, including 3D modeling, clash detection, project management, and collaboration techniques. These institutes provide hands-on training with industry-standard software like Revit, Navisworks, and ArchiCAD, equipping students with practical skills that are highly valued in the construction sector. With the construction industry increasingly shifting towards digital workflows, professionals skilled in BIM are in high demand, making this training essential for career advancement.

Moreover, a good BIM training institute in Pune not only focuses on technical skills but also emphasizes real-world application through project-based learning, internships, and certification programs. Such institutes often collaborate with leading architecture, engineering, and construction firms, providing students with networking opportunities and industry insights. Graduates from these programs often find themselves better positioned to secure lucrative roles in design firms, construction companies, and infrastructure projects across Pune and beyond.

Plastic Domain Training Institute in Pune

In addition to the BIM domain, Pune also hosts specialized training institutes in the Plastic domain. Plastic manufacturing, processing, and product design are crucial sectors in the city’s industrial landscape. A dedicated Plastic domain training institute in Pune provides courses that cover plastic injection molding, extrusion, blow molding, and material properties. These programs are designed for students and professionals looking to deepen their understanding of plastics technology, quality control, and innovation in plastic products.

Such institutes focus on practical skill development, often offering workshops on CAD for plastic product design, mold design, and testing procedures. As industries like packaging, automotive, healthcare, and consumer goods heavily rely on plastics, expertise in this domain opens various career opportunities. Graduates can work as plastic process engineers, quality analysts, or product designers, contributing to Pune's expanding manufacturing ecosystem.

Choosing a reputable plastic training institute in Pune ensures that students receive industry-relevant knowledge, access to state-of-the-art equipment, and mentorship from experienced instructors. This targeted training helps bridge the gap between theoretical understanding and practical application, preparing students to meet industry standards and innovate within the plastic domain.

Mechanical CAD Training in Pune & CAD Interior Design

For students inclined towards design and engineering, Mechanical CAD Training in Pune is an ideal pathway. Mechanical CAD (Computer-Aided Design) involves drafting, modeling, and simulation of mechanical components and systems. Institutes offering specialized Mechanical CAD training focus on popular software like SolidWorks, AutoCAD, Creo, and CATIA. These courses empower students to create detailed 3D models, perform simulations, and prepare manufacturing drawings, essential skills in mechanical engineering and product design.

Additionally, the field of CAD interior design has gained significant popularity, especially in Pune’s booming real estate and hospitality sectors. CAD interior design courses teach students how to utilize software such as AutoCAD, SketchUp, and 3ds Max to create detailed interior layouts, visualizations, and renderings. These programs are tailored for aspiring interior designers, architects, and decorators who wish to translate their creative ideas into precise digital models.

Both these training areas—Mechanical CAD and CAD interior design—offer excellent career prospects. Mechanical CAD professionals find roles in manufacturing, automotive, aerospace, and industrial design sectors, while CAD interior designers are in demand within architecture firms, interior design studios, and construction companies. The key to success in these fields lies in choosing a reputed training institute that provides comprehensive coursework, practical exposure, and industry mentorship.

Conclusion

In summary, Pune offers a multitude of training opportunities for aspiring professionals in the domains of BIM, plastics, mechanical CAD, and interior design. Whether you aim to excel in Bim Training Institute in Pune, specialize in Plastic domain training institute in Pune, or pursue Mechanical CAD Training in Pune with a focus on cad interior design, there are institutes tailored to meet your career goals. Ensuring you select a reputed institute with industry connections and hands-on learning will significantly boost your employability and skillset.

0 notes

Text

B.Tech in Mechanical Engineering: A Timeless Branch with Limitless Possibilities

Mechanical Engineering is often referred to as the “evergreen branch” of engineering—and for good reason. It is one of the oldest and broadest disciplines, involving the design, development, manufacturing, and maintenance of mechanical systems. If you're someone who enjoys understanding how machines work and are passionate about innovation, then B.Tech in Mechanical Engineering could be the perfect course for you.

In the age of automation, robotics, and sustainable energy, mechanical engineers are playing a critical role in shaping the future. From automobiles and aerospace to energy systems and manufacturing, the scope is vast and continuously evolving.

What is B.Tech in Mechanical Engineering?

B.Tech in Mechanical Engineering is a four-year undergraduate program that provides students with a strong foundation in physics, mathematics, material science, thermodynamics, mechanics, and design principles. It blends theoretical knowledge with practical skills through laboratory work, industry projects, internships, and workshops.

Students learn to use advanced software like AutoCAD, SolidWorks, ANSYS, and MATLAB to design and analyze mechanical systems. In addition to core mechanical subjects, modern programs also include electives like robotics, artificial intelligence in manufacturing, and green energy technologies.

Why Choose Mechanical Engineering?

Mechanical engineering is ideal for students who are creative, analytical, and have a keen interest in building and improving machines or mechanical systems. Here are a few key reasons why this branch remains a top choice:

Versatile Career Options: Mechanical engineers can work in industries like automotive, aerospace, energy, HVAC, robotics, and even healthcare.

Global Demand: It is a globally recognized field with high employment potential both in India and abroad.

Gateway to Innovation: Mechanical engineers often lead innovation in product development, sustainable technologies, and automation.

Strong Earning Potential: With the right skills and experience, professionals can enjoy a lucrative career.

Career Opportunities After B.Tech in Mechanical Engineering

Graduates from B.Tech in Mechanical Engineering programs have a wide array of career paths available:

Design Engineer

Production Engineer

Quality Control Engineer

Maintenance Engineer

HVAC Engineer

CAD/CAE Analyst

Research & Development Engineer

Project Manager

Those interested in higher studies can pursue M.Tech, MBA, or specialized certifications in areas like mechatronics, 3D printing, or AI in manufacturing.

Choose the Right College: IILM College Greater Noida

For students seeking a high-quality engineering education, IILM College of Engineering and Technology, Greater Noida, stands out as a top choice. Recognized for its excellence in technical education, IILM offers a comprehensive B.Tech in Mechanical Engineering program that combines academic rigor with hands-on learning.

Here’s why IILM Greater Noida is considered a leading Mechanical Engineering College in Greater Noida:

Experienced Faculty: Learn from industry experts and PhD holders.

State-of-the-art Labs: Equipped with modern tools and simulation software.

Industry Exposure: Internships, live projects, and industrial visits.

Career Support: Strong placement cell with ties to top companies in manufacturing, automotive, and design sectors.

Skill Development: Emphasis on soft skills, leadership, and entrepreneurship.

1 note

·

View note

Text

Case Study: How a Custom Plastic Mould Cut Production Time by 30%

In the manufacturing world, time is money. As India’s “Make in India” drive gains momentum, companies are improving their plastic moulding processes to cut costs and turnaround times. This case study shows how a Pune-based FMCG supplier cut down production time by 30 percent. The company switched to a custom plastic mould. At the same time, the quality was maintained.

The Challenge: Slow Cycle Time Delayed Deliveries

The medium-sized company ABC Packaging is a homecare plastic dispenser supplier. Its injection moulding unit was using old, generic moulds. When the orders increased after the COVID pandemic, it couldn’t keep up with the demand because of slow cycle times. It took 42 seconds to make a dispenser, far above industry benchmarks. Customers started complaining when shipments were delayed. The company decided to optimize its operations.

ABC Packaging Collaborated with XYZ Polymoulds

To solve the problem, ABC decided to work with the best plastic mould manufacturer in India. The company engaged XYZ Polymoulds renowned for providing innovative industrial moulding solutions. XYZ’s engineers carried out a comprehensive process audit. The company recommended a high-efficiency mould design, keeping in mind the product features and material used.

XYZ developed a custom plastic mould. It consisted of precision-vented gates, advanced cooling channels, and a multi-cavity layout. This enabled ABC to make more units in one shot. The innovative design reduced the cycle time and ensured consistent product quality.

Results: Production Increased and Costs Reduced

The new mould enhanced plastic production efficiency and cycle time per unit fell 30% from 42 seconds to 29 seconds. Furthermore, scrap rates declined by 18% due to better cooling and uniform material distribution. This enabled ABC to easily meet customer deadlines, cut down overtime labour costs, and increase daily production without installing additional machines.

Manufacturers in the region hail ABC’s success story as the best plastic moulding case study as it helps them to scale their businesses with smart investments rather than investing in more machinery.

Why It Worked?

This case study highlights the plastic mould design benefits that accrue because of investing in time-saving mould design in India. They include:

Lower energy consumption

Reduced maintenance downtime

Improved mould life

There is a demand for rapid growth in the manufacturing sector. More and more businesses are seeking cost-effective injection moulding solutions in India.

India’s Plastic Moulding Industry Outlook In 2025

According to the All India Plastics Manufacturers Association (AIPMA), plastic processing capacity in India is expected to touch 34 million tonnes this year. This boom is driving plastic moulding process improvement, especially among small and medium enterprises. Furthermore, the increased access to CNC machining, thermal imaging, and simulation software is enabling even budget-conscious manufacturers to reap the benefits of moulding cost reduction in India.

Conclusion

This case study shows that businesses of all sizes can benefit from innovative mould designs. Are you still using standard tools for your specialized product? If yes, it is time to rethink and redesign your tools. Speeding up production without incurring scaling costs starts with the right mould!

FAQs

1. Custom plastic mould vs generic mould – Which is better?

Answer: A custom plastic mould is designed keeping in mind your product’s shape, size, and production aspects. Unlike generic moulds, it offers speed, accuracy, and durability.

2. Do custom moulds help reduce production time?

Answer: Yes. As explained in the case study, custom mould designs come with optimized cooling, gating, and layout. They can cut cycle time by 20% to 40%. They help reduce production time with moulding.

3. How to choose a reliable plastic mould manufacturer in India?

Answer: Choose a company with in-house designers and modern tools and equipment. The company should also have a proven track record of providing the best injection moulding solutions in India.

4. Are high-efficiency moulds expensive?

Answer: Initial costs can be higher. However, the long-term benefits include increased plastic production efficiency and moulding cost reduction in India.

#mould manufacturer#plastic mould maker#awanti polymoulds#mould manufacturer in india#blow mold manufacturers#awantipolymoulds#high speed bottle moulds#pet blow mould#mouldmanufacturers#blow mould manufacturer

0 notes

Text

#quantumcomputing#3d printing#cfd#additive manufacturing#cfd simulation#hvac services#3d printing simulation software#simulation#technology#aerospace engineering#additive manufacturing software#3d sculpting#blender#ai generated#artificial intelligence

0 notes

Text

Unlock Innovation: How Solid Edge CAD Software Can Revolutionize Your Business

In today’s competitive landscape, design and manufacturing companies are constantly seeking an edge. The ability to innovate faster, design with greater precision, and bring products to market quicker is paramount. This is where powerful CAD software becomes not just a tool, but a strategic advantage. At DDSPLM, we’re passionate about empowering businesses with the right technology. And when it comes to cutting-edge CAD solutions, Solid Edge stands out from the crowd.

What is Solid Edge CAD Software?

Solid Edge is a comprehensive and user-friendly 3D CAD (Computer-Aided Design) software that offers best-in-class capabilities for product design, simulation, manufacturing, and data management. Developed by Siemens Digital Industries Software, it’s renowned for its unique Synchronous Technology, which combines the speed and flexibility of direct modeling with the precision of parametric design.

Features:

Synchronous Technology

Generative Design

Additive Manufacturing (3D Printing) Capabilities

Cloud-Based Collaboration

Integrated Simulation Tools

Robust Assembly Design

2D Drafting & Annotation

Electromechanical Design

How Solid Edge CAD Software Can Transform Your Business:

Accelerated Product Development

Enhanced Innovation

Improved Product Quality

Reduced Costs

Seamless Collaboration

Increased Efficiency

Why Choose DDSPLM?

At DDSPLM, we’re more than just a software reseller; we’re your trusted partner in digital transformation.

Expertise

Comprehensive Support

Tailored Solutions

Commitment to Your Success

Conclusion:

In a world that demands continuous innovation, Solid Edge CAD software offers the power, flexibility, and intelligence to keep you ahead of the curve. By partnering with DDSPLM, you’re not just investing in software; you’re investing in a future of accelerated innovation, improved efficiency, and unparalleled success.

0 notes

Text

Safety Standards Followed by Leading Plate Heat Exchanger Manufacturers in Pune

In the evolving industrial landscape, safety is no longer just a checkbox—it’s a non-negotiable priority. This holds especially true in thermal system manufacturing, where heat, pressure, and complex engineering converge. Among the key players in this space, plate heat exchanger manufacturers in Pune have emerged as leaders, not just in innovation and performance, but also in following strict safety standards.

Pune, known for its robust engineering ecosystem, houses several reputable manufacturers that design and supply plate heat exchangers for industries like chemical processing, pharmaceuticals, food and beverage, HVAC, and more. What sets a trusted plate heat exchanger manufacturer in Pune apart is their unwavering commitment to safety across every stage—design, fabrication, assembly, testing, and delivery.

Let’s explore the various safety standards followed by the top manufacturers in Pune and how these practices contribute to long-term equipment reliability and user safety.

1. Compliance with International Design Codes

Every leading plate heat exchanger manufacturer in Pune adheres to globally recognized design codes such as ASME (American Society of Mechanical Engineers), TEMA (Tubular Exchanger Manufacturers Association), and PED (Pressure Equipment Directive). These standards ensure that each heat exchanger can handle its intended pressure, temperature, and operating conditions without failure.

For manufacturers, following these codes isn't just about passing an inspection—it reflects engineering integrity. Pune-based manufacturers frequently invest in advanced design software and simulation tools that ensure every design meets these regulatory benchmarks with precision.

2. Material Safety and Traceability

Raw materials play a vital role in the performance and safety of a plate heat exchanger. Reliable plate heat exchanger manufacturers in Pune source certified materials with proper documentation, including chemical composition and mechanical properties.

High-grade stainless steel, titanium, and other corrosion-resistant alloys are used depending on the application. These manufacturers maintain full traceability, so if any issues arise post-installation, the specific material batch can be tracked and analyzed. This traceability is a cornerstone of ISO 9001 and other quality systems followed by Pune-based companies.

3. Pressure Testing and Leak-Proof Assurance

Before leaving the factory, every unit undergoes rigorous hydrostatic and pneumatic testing. These tests are done under pressure conditions that exceed actual operating parameters to ensure the system can withstand extreme conditions.

This is a routine but essential practice for any professional plate heat exchanger manufacturer in Pune. It prevents unexpected system failures, especially in industries like oil and gas or chemical processing where safety risks are higher.

4. Welding and Assembly Safety Protocols

Precision welding is critical to the performance of plate heat exchangers, especially in gasketed and brazed models. Pune manufacturers employ certified welders and follow welding standards such as ASME Section IX and ISO 9606. In addition, many manufacturers implement cleanroom conditions for final assembly, ensuring that no contaminants affect sealing surfaces.

By maintaining strict welding procedures, these companies reduce the risk of joint failures, leakage, or structural compromise—all of which can have serious safety consequences.

5. Regular Staff Training and Certification

Safety begins with the people on the shop floor. Top plate heat exchanger manufacturers in Pune ensure that every technician, engineer, and production worker is regularly trained on workplace safety, quality protocols, and handling of high-pressure components.

Many companies also participate in third-party audits and safety workshops to stay updated with evolving safety standards. Employee safety gear, SOPs for emergency handling, and regular mock drills are standard practices.

6. Environmental and Workplace Safety Compliance

Environmental safety is another area where Pune’s manufacturers excel. Compliance with local and international environmental norms ensures that no harmful by-products are released during manufacturing. Proper waste disposal, use of eco-friendly cleaning agents for plates, and energy-efficient processes all contribute to both worker and environmental safety.

Factories are routinely inspected for fire safety, electrical hazard prevention, and ventilation control. This not only safeguards workers but also ensures uninterrupted and clean production environments.

Conclusion

When selecting a plate heat exchanger manufacturer in Pune, safety should be one of your top evaluation criteria. From global design compliance to pressure testing, from material traceability to employee training—these manufacturers invest heavily in building safe, reliable, and high-performing products. Their dedication to maintaining world-class safety standards not only enhances the quality of the equipment but also ensures peace of mind for clients across various industries.

Choosing a manufacturer that prioritizes safety is not just a smart business decision—it’s a long-term investment in operational stability and human well-being.

0 notes

Text

Plastic Injection Molding Parts | Designed To Your Specs

Plastic Injection Molding Parts are important additives used at some point of industries together with car, medical, electronics, consumer gadgets, and packaging. This manufacturing machine allows the mass production of plastic components with excessive precision, repeatability, and rate-effectiveness.

What is Plastic Injection Molding?

Plastic injection molding is a system in which molten plastic is injected into a mildew hollow region beneath immoderate stress. The plastic cools and solidifies, taking the form of the mold. Once cooled, the mold opens and the issue is ejected. This cycle may be repeated suddenly, making it perfect for high-amount manufacturing.

Characteristics of Injection Molded Parts

Plastic Injection Molding Parts Suppliers in China are stated for their durability, complexity, and tight tolerances. They can variety from easy family gadgets like bottle caps to complex elements like medical tool housings or vehicle connectors.

Key characteristics include:

High precision: Molds are designed with intense accuracy, regularly indoors with a tolerance of ±0.001 inch.

Repeatability: Every element produced in a mould is kind of identical, making sure product consistency.

Surface surrender: Injection molding can obtain clean or textured finishes straight away from the mildew.

Material versatility: An excellent type of thermoplastics may be used, which include ABS, polycarbonate, nylon, polypropylene, and extra.

Common Applications

Plastic Injection Molding Parts Manufacturer in China are discovered in nearly every area:

Automotive: Dashboards, moderate housings, clips, and handles.

Medical: Syringe our bodies, housings for diagnostic devices, and surgical device additives.

Consumer electronics: Casings for phones, a protracted manner of controls, and keyboards.

Packaging: Lids, containers, and closures.

Each software wishes special popular common performance tendencies, which includes UV resistance, flame retardancy, or effect electricity, which may be finished through material preference and mould layout.

Design Considerations

To create first-rate molded elements, several elements should be taken into consideration for the duration of the design phase:

Wall thickness: Uniform wall thickness ensures right filling and minimizes warping.

Draft angles: Slight angles on vertical partitions help with element ejection.

Ribs and managers: Used for structural assist or attachment points.

Undercuts: Require component-movements or collapsible cores, developing mould complexity.

Using laptop-aided layout (CAD) and simulation software program software allows in optimizing the issue format for manufacturability.

Advantages of Plastic Injection Molding Parts

Efficiency in excessive volumes: Once the mildew is made, factors may be produced fast and at low price in step with unit.

Material standard performance: Excess plastic can frequently be recycled and reused.

Strength and consistency: Engineered plastics can shape the power of metals in a few programs.

Automation: Injection molding techniques are pretty automated, reducing hard paintings expenses and mistakes.

Conclusion

Plastic Injection Molding Parts in China play a vital function in modern-day manufacturing. Their versatility, precision, and fee-effectiveness lead them to best for mass manufacturing in the course of numerous industries. With non-prevent advances in materials and mildew generation, the functionality for innovation in plastic component format and feature continues to develop.

#Plastic Injection Molding Parts#Plastic Injection Molding Parts in China#Plastic Injection Molding Parts Supplier#Plastic Injection Molding Part

0 notes

Text

VR VFX studio

What a VR VFX Studio Brings to Immersive Experience Development

Overview of a VR VFX Studio’s Role

A VR VFX studio specializes in creating visual effects specifically for virtual reality environments. These studios focus on producing dynamic, immersive visuals that respond in real time to user input, movement, and interaction. The visual effects in VR must support 360-degree navigation, stereoscopic depth, and real-time rendering—all while maintaining realism and performance across a variety of devices. The goal is to enhance the user’s sense of presence inside virtual spaces through tailored, reactive VFX design.

Unlike traditional post-production studios, a VR VFX studio works within the framework of real-time engines, building visuals that are experienced interactively instead of passively viewed. This shift from linear to immersive content changes how VFX are conceived, structured, and deployed, making technical precision and optimization central to the development process.

Services Offered by VR VFX Studios

VR VFX studios typically offer a wide range of services designed to support immersive content creation from concept to execution. These include spatial VFX design, particle systems for environmental effects, custom shader development, and real-time animation for interactive scenarios. Lighting, shadow simulation, and volumetric rendering are tailored for full-scene immersion.

A key aspect is interactive VFX scripting—developing visual responses triggered by user actions such as gaze, motion, gesture, or voice. For instance, sparks may fly when an object is touched, or fog may move as the user walks through a scene. Studios also focus on VR-specific requirements such as maintaining consistent frame rates, stereo depth alignment, and ensuring comfort by avoiding effects that could cause disorientation.

In addition, they provide cross-platform deployment, adjusting visuals to perform smoothly across different VR systems, including tethered headsets, standalone devices, and mobile VR solutions.

Industry Use of VR Visual Effects

VR VFX studios support industries far beyond entertainment. In healthcare, they help design surgical training modules that replicate real-world procedures with accurate tissue behavior and biological effects. In education, VFX brings to life interactive 3D models of historical events, scientific processes, or technical systems, making learning more engaging.

Architectural firms rely on VR effects to simulate lighting shifts, environmental changes, or material transitions within virtual walkthroughs. The manufacturing and automotive sectors use VFX to enhance VR prototyping, assembly training, and safety simulations.

Entertainment remains a major driver, with VR games, cinematic experiences, and theme park attractions all demanding high-end VFX for realism and narrative depth. Here, VFX simulate anything from magical environments and futuristic cities to photorealistic recreations of historical settings.

Tools and Technology in Use

VR VFX studios primarily work within real-time engines like Unreal Engine and Unity, which offer extensive support for immersive content development. These engines enable the integration of GPU-based visual effects, advanced lighting systems, and dynamic scene rendering.

Artists use a range of 3D modeling, simulation, and texturing tools to build detailed assets. These include sculpting software for characters, physics engines for destruction or fluid simulation, and procedural generation tools for landscapes and weather systems.

Optimization tools ensure visual performance meets the high frame rate requirements of VR hardware, while debugging tools help fine-tune user experience issues such as latency or stereoscopic distortion. VFX teams also integrate motion capture and spatial tracking data to align visuals with real-world inputs.

Evolving Scope of VR VFX Studios

As virtual reality continues to grow, VR VFX studios are taking on increasingly complex and interactive projects. Trends include AI-generated environmental effects, integration with haptic feedback systems, and cloud-based rendering for scalable performance. Studios are also exploring hybrid experiences that combine VR with real-world elements through sensor input and mixed reality integration.

The growing demand for rich, believable VR content positions these studios at the center of innovation in immersive technology. Their work not only defines how users perceive virtual environments but also shapes how industries deliver training, storytelling, and digital experiences in a fully immersive format.

0 notes

Text

Introduction to CODESYS PLC: A Comprehensive Overview

CODESYS (Controller Development System) is a leading software platform for industrial automation, widely used for programming and configuring Programmable Logic Controllers (PLCs). Developed by the German company 3S-Smart Software Solutions, CODESYS PLC is a versatile, hardware-independent development environment that supports a broad range of industrial applications, from factory automation to process control and motion control systems. This article explores the key features, benefits, programming capabilities, and applications of CODESYS PLC, highlighting its significance in modern industrial automation.

What is CODESYS?

CODESYS is an integrated development environment (IDE) that adheres to the international standard IEC 61131-3, which defines programming languages for PLCs. This standard ensures that CODESYS is compatible with a wide variety of hardware platforms from different manufacturers, making it a flexible and scalable solution. The platform supports all five IEC 61131-3 programming languages: Ladder Diagram (LD), Function Block Diagram (FBD), Structured Text (ST), Instruction List (IL), and Sequential Function Chart (SFC). Additionally, CODESYS extends support for object-oriented programming (OOP) with languages like Structured Text, enabling advanced programming techniques.

The CODESYS ecosystem includes not only the core IDE but also additional tools for visualization, simulation, debugging, and communication with field devices. It is used in industries such as manufacturing, energy, automotive, and building automation, offering a unified platform for developing complex automation solutions.

Key Features of CODESYS

IEC 61131-3 Compliance: CODESYS supports all standard PLC programming languages, allowing developers to choose the most suitable language for their application. This compliance ensures portability of code across different PLC hardware, reducing development time and costs.

Hardware Independence: CODESYS is compatible with over 1,000 devices from various manufacturers, including Siemens, Beckhoff, WAGO, and others. This flexibility allows engineers to write code once and deploy it on multiple platforms without significant modifications.

Integrated Visualization: CODESYS provides built-in tools for creating Human-Machine Interfaces (HMIs). Developers can design graphical user interfaces for operator panels, web-based visualizations, or mobile applications, all within the same environment.

Fieldbus and Communication Support: The platform supports a wide range of industrial communication protocols, such as Modbus, CANopen, EtherCAT, PROFINET, and OPC UA. This ensures seamless integration with sensors, actuators, and other devices in an automation system.

Simulation and Debugging: CODESYS includes a powerful simulation mode that allows developers to test their programs without physical hardware. The debugging tools enable real-time monitoring, breakpoints, and variable tracing, streamlining the development process.

Scalability and Modularity: From small embedded systems to large distributed control systems, CODESYS is highly scalable. Its modular architecture allows developers to add libraries, function blocks, and extensions as needed.

Safety and Security: CODESYS supports safety programming according to standards like IEC 61508 (SIL 2/3), making it suitable for safety-critical applications. It also includes features for secure communication and user authentication to protect against cyber threats.

Programming with CODESYS

CODESYS offers a flexible programming environment that caters to both novice and experienced developers. The five IEC 61131-3 languages provide diverse options:

Ladder Diagram (LD): Ideal for electrical engineers familiar with relay logic, LD resembles electrical circuit diagrams and is widely used for simple control tasks.

Function Block Diagram (FBD): A graphical language that uses blocks to represent functions, making it intuitive for designing complex systems.

Structured Text (ST): A high-level, text-based language similar to Pascal or C, suitable for algorithmic and mathematical operations.

Instruction List (IL): A low-level, assembly-like language for precise control, though less commonly used today.

Sequential Function Chart (SFC): Used for sequential control processes, SFC is ideal for applications requiring step-by-step execution, such as batch processing.

In addition to these, CODESYS supports object-oriented programming, allowing developers to create reusable code through classes, methods, and inheritance. This is particularly useful for large-scale projects where modularity and maintainability are critical.

Benefits of Using CODESYS

Cost Efficiency: By supporting multiple hardware platforms, CODESYS eliminates the need for proprietary software tied to specific vendors, reducing licensing and development costs.

Flexibility: Developers can work in their preferred programming language and deploy code on various devices, enhancing project flexibility.

Community and Ecosystem: CODESYS has a large user base and an active community, with extensive documentation, libraries, and third-party tools available through the CODESYS Store.

Rapid Development: The integrated environment, combined with simulation and debugging tools, accelerates development and testing cycles.

Global Adoption: CODESYS is used worldwide, ensuring that skills learned in the platform are transferable across industries and regions.

Applications of CODESYS PLC

CODESYS is employed in a wide range of industries, including:

Manufacturing: Controlling assembly lines, robotic systems, and CNC machines.

Energy: Managing renewable energy systems, such as wind turbines and solar plants, as well as traditional power distribution networks.

Building Automation: Integrating HVAC, lighting, and security systems for smart buildings.

Automotive: Controlling production lines and testing equipment in automotive manufacturing.

Process Control: Managing chemical plants, water treatment facilities, and food processing systems.

Getting Started with CODESYS

To begin using CODESYS, developers can download the free CODESYS Development System from the official website. The software is compatible with Windows and supports a variety of PLC hardware. Beginners can start with the extensive documentation and tutorials available online, while advanced users can explore the CODESYS Store for additional libraries and add-ons.

A typical workflow involves:

Installing the CODESYS IDE.

Selecting a target PLC and configuring the hardware.

Writing the program using one or more IEC 61131-3 languages.

Simulating the program to test functionality.

Deploying the code to the PLC and monitoring its performance.

Challenges and Considerations

While CODESYS is a powerful platform, there are some considerations:

Learning Curve: For beginners, mastering all five programming languages and the IDE’s features can take time.

Hardware Dependency: Although CODESYS is hardware-independent, specific PLCs may require proprietary drivers or configurations.

Licensing: While the core IDE is free, certain add-ons, libraries, or runtime licenses may incur costs, depending on the application.

Conclusion

CODESYS PLC by Servotechinc is a cornerstone of modern industrial automation, offering a robust, flexible, and scalable platform for PLC programming. Its adherence to IEC 61131-3, support for multiple programming languages, and extensive feature set make it a preferred choice for engineers worldwide. Whether you’re developing a small control system or a complex, distributed automation solution, CODESYS provides the tools to streamline development and ensure reliable performance. As industries continue to embrace digital transformation, CODESYS remains at the forefront, empowering automation professionals to build the systems of the future.

0 notes